1NO1NC Push Button Switch Guide | HBAN Push button

Introduction to 1no1nc Push Button Switch

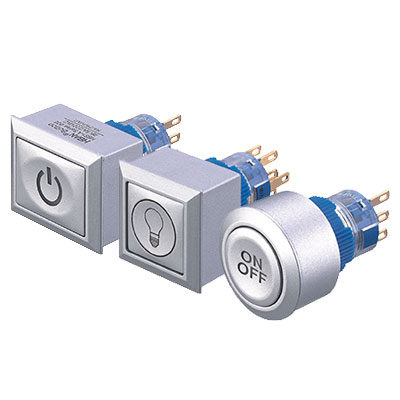

The 1no1nc Push Button Switch is a versatile and essential component in modern electrical systems. This switch features one normally open (NO) and one normally closed (NC) contact, allowing it to serve dual functions in various applications.

Designed for reliability and ease of use, the 1no1nc Push Button Switch is commonly found in control panels, machinery, and automation systems. Its robust construction ensures durability, making it suitable for both industrial and commercial environments.

With a simple press, users can easily toggle between activating and deactivating circuits. This makes the switch ideal for applications requiring immediate response, such as emergency stop mechanisms or start controls.

The 1no1nc configuration enhances flexibility, enabling seamless integration into complex control systems. Additionally, its compact design allows for easy installation in tight spaces.

Understanding the Basics of 1NO1NC Push Button Switches

The 1NO1NC push button switch is a fundamental component in electrical circuits, playing a crucial role in controlling various devices. The term "1NO1NC" refers to its configuration: one normally open (NO) contact and one normally closed (NC) contact. This unique setup allows for versatile applications, enabling users to either complete or break a circuit with a simple press.

When the push button is activated, the normally open contact closes, allowing current to flow. Simultaneously, the normally closed contact opens, interrupting any existing current in that path. This dual functionality makes the 1NO1NC push button switch ideal for applications such as machinery controls, alarms, and lighting systems.

Typically constructed from durable materials, these switches are designed for longevity and reliability. They come in various styles and sizes, catering to different installation needs and user preferences. Understanding how to properly utilize a 1NO1NC push button switch can significantly enhance the efficiency of electrical systems.

Applications of 1no1nc Push Button Switches

In industrial settings, 1no1nc Push Button Switches are often employed in control panels for machinery. They allow operators to start or stop equipment efficiently, enhancing safety and productivity.

In the realm of consumer electronics, these switches are commonly used in household appliances, such as washing machines and microwaves. Their reliability ensures that users can easily operate these devices with just a simple press.

Additionally, 1no1nc Push Button Switches are integral to automotive applications. They serve functions like activating headlights or horn systems, providing drivers with essential controls at their fingertips.

Moreover, these switches are increasingly used in automation systems. Their ability to facilitate quick responses makes them perfect for emergency stop functions, ensuring immediate action can be taken in critical situations.

Overall, the adaptability of 1no1nc Push Button Switches across multiple domains highlights their importance in modern technology. Whether in industrial, consumer, or automotive applications, they play a crucial role in enhancing functionality and safety.

Key Features of 1no1nc Switches

The core feature of the 1NO1NC switch is that it has both a Normally Open (NO) contact and a Normally Closed (NC) contact.

Normally Open (NO) contact: When the switch is not operated, the circuit is disconnected. When an operating force is applied (such as pressing a button or flipping a switch), the NO contact closes and the circuit is connected.

Normally Closed (NC) contact: When the switch is not operated, the circuit is connected. When an operating force is applied, the NC contact opens and the circuit is disconnected.

This unique contact configuration enables the 1NO1NC switch to achieve two opposite control functions in one switching action, greatly simplifying circuit design and improving system reliability.

Troubleshooting Common Issues with 1no1nc Switches

1NO1NC switches play an important role in a variety of applications with their versatility. However, like any electronic component, they can also encounter some common problems. Knowing how to diagnose and solve these problems is essential to ensure that your circuit operates properly. This article will explore some common 1NO1NC switch failures and how to troubleshoot them.

Common Problem 1: Switch Not Responding (Both NO and NC Contacts Not Acting as Expected)

This can be one of the most frustrating problems. When you operate the switch, nothing changes in the circuit. Here are some possible troubleshooting steps:

1. Check the power supply: Make sure that the circuit containing the switch is powered. Check that the power supply is stable and the fuse is not blown.

2. Check the mechanical connection: Confirm that the physical connection of the switch is secure. For example, if it is a push button switch, check if the button is stuck or blocked. If it is a toggle switch, check if the toggle lever is loose or damaged.

3. Check the electrical connection: Carefully check all wires connected to the switch terminals. Make sure they are securely connected and not loose or broken. You can use a multimeter to check the continuity of the line.

4. Check for internal switch failure: Mechanical or electrical components inside the switch may have been damaged. If possible, try using a multimeter to measure the state of the NO and NC contacts when they are operated and not operated. Ideally, the NC contacts should be conducting (low resistance or close to zero) and the NO contacts should be disconnected (high resistance or open circuit) when not operated. After operation, the situation should be the opposite. If the readings are not as expected, the switch may need to be replaced.

Common Problem 2: Normally Open (NO) Contacts Fail to Close

When the switch is operated, the normally open contact should close to complete the circuit, but if it does not respond, try the following:

1. Check mechanical movement: Make sure the switch's operating mechanism (such as buttons, levers) can move freely and can fully contact the internal contacts when operated.

2. Check for contact contamination or oxidation: Dust, dirt or oxides may accumulate on the contact surface, resulting in poor contact. The contacts can be carefully cleaned with a contact cleaner. Always disconnect the power supply before cleaning.

3. Check for internal damage: A spring or other mechanical part inside the switch may be damaged, causing the contacts to not close properly. This usually requires replacing the switch.

Common Problem 3: Normally Closed (NC) Contacts Fail to Open

A normally closed contact should be conductive when not operated and open when operated. If it remains conductive, check:

1. Check for blocked mechanical movement: Similar to the NO contact problem, make sure the switch's operating mechanism can properly open the NC contacts when operated. Is there any foreign material blocking the switch's movement?

2. Check for stuck contacts: In some cases, the contacts may stick together due to overcurrent or other reasons, causing them to not open even after operation. This usually requires replacing the switch.

3. Check for internal damage: An internal mechanical part may be damaged, causing the NC contacts to not open.

Common Problem 4: Intermittent Poor Contact

This is a more difficult problem to diagnose, where the circuit sometimes works properly and sometimes fails. Possible causes include:

1. Loose connections: Wire connections may be good and bad. Double-check all connections to make sure they are tight and secure.

2. Contact contamination: Slight contact contamination can cause intermittent poor contact. Try cleaning the contacts.

3. Internal switch failure: There may be fatigue or slight damage to the components inside the switch, causing intermittent failure. If an internal failure is suspected, it is best to replace the switch.

4. Environmental factors: Changes in temperature or humidity can sometimes affect the performance of the switch. Check that the switch is used within the recommended operating environment range.

Prevention is better than cure

To reduce the possibility of problems with 1NO1NC switches, you can take some precautions:

1. Choose a high-quality switch: Use a switch produced by a reputable manufacturer that meets the application requirements.

2. Proper installation and wiring: Follow the manufacturer's guidelines for installation and wiring.

3. Avoid overloads: Do not exceed the rated current and voltage of the switch.

4. Regular maintenance: Clean and inspect when necessary.

Benefits of Using 1no1nc Push Button Switches

1. Integrated dual functions: simplify design and save space

The core advantage of the 1NO1NC push switch is that it integrates a normally open (NO) contact and a normally closed (NC) contact in a compact unit. This means that with one press, you can simultaneously implement two opposite circuit control logics.

For example: when the button is pressed, one circuit is connected (NO closed) and the other circuit is disconnected (NC disconnected). After releasing the button, the circuit status returns to the original state (NO disconnected, NC closed).

This integrated dual function design significantly simplifies circuit design and reduces the number of required components, thereby saving valuable space, especially in space-constrained applications.

2. Flexible control scheme: meet diverse needs

The versatility of the 1NO1NC push switch enables it to adapt to a variety of complex control needs, providing engineers and designers with greater flexibility:

Start/stop and indication: A single button can be used to start the device (NO closed) and turn off the operating indicator light (NC disconnected), or vice versa.

Selection and switching functions: By pressing the operation, you can quickly switch between two different modes or functions.

Interlocking and safety applications: In the safety circuit, NO and NC contacts can be used to implement an interlocking mechanism to ensure that when one action occurs, the other action is blocked, thereby improving the safety of the system.

Status feedback: Combined with the indicator light, clear system status feedback can be provided through the operation of a button and the change of the indicator light state.

3. Reduce costs: Reduce components and wiring

Compared to using two independent normally open and normally closed push switches to achieve the same function, it is undoubtedly more cost-effective to use a single 1NO1NC push switch. It not only reduces the number of switches required, but also simplifies the wiring and installation process, reducing material costs and labor costs.

4. Improve reliability: Reduce connection points

Fewer components means fewer connection points, which generally improves the reliability of the entire system. Each connection point has a potential risk of failure, and the 1NO1NC push switch reduces these potential failure points by integrating functions.

5. Simplified maintenance: easier troubleshooting

When the number of switches used in the system is reduced, maintenance and troubleshooting will also become simpler. If a problem occurs, there are fewer switches to check, making it easier to locate the cause of the problem.

6. Intuitive operation: user-friendly experience

For the end user, a single button to achieve multiple control functions is usually more intuitive and convenient to operate, improving the user experience.

Choosing the Right 1NO1NC Push Button Switch

Selecting the right 1NO1NC pushbutton switch is essential to ensuring your circuit operates safely and reliably. There are a wide variety of models and specifications available on the market, so it is vital to carefully consider several key factors. Here are some important aspects to consider when choosing a 1NO1NC pushbutton switch:

1. Electrical Rating (Current and Voltage Rating): This is the first consideration. Be sure to select a switch with a current and voltage rating equal to or higher than your circuit requires. Exceeding the switch's rating may result in overheating, contact meltdown, or even worse failures. You need to consider the ratings for both AC and DC circuits and ensure that the selected switch is suitable for your application.

2. Switch Function (Momentary vs. Latching): 1NO1NC pushbutton switches can be momentary or latching.

Momentary: The contact state changes only when pressed and returns to the original state immediately after release. Commonly used in applications such as start, stop, or pulse signals.

Self-locking type: After pressing once, the contact state remains unchanged, and it needs to be pressed again to return to the original state. Commonly used for power switches or controls that need to maintain the state.

Choose the appropriate function type according to your application requirements.

3. Contact material and type: The quality of the contact material directly affects the life and reliability of the switch. Common contact materials include silver alloys, gold alloys, etc. Gold alloy contacts usually have better oxidation resistance and conductivity, and are suitable for low-current applications and occasions requiring high reliability. The type of contact will also affect its performance and life.

4. IP protection rating (Ingress Protection Rating): If the switch needs to be used in harsh environments, such as dusty or humid places, then the IP protection rating is very important. Choosing a switch with an appropriate IP rating can ensure that it is protected from environmental factors and ensure long-term reliable operation.

5. Mechanical life (Mechanical Life): The number of operations that a switch can withstand is an important indicator, especially in applications that require frequent operations. Mechanical life is usually expressed as "how many cycles". Choosing a switch with sufficient mechanical life can reduce the frequency of replacement.

6. Actuation Force: The force required to operate the switch also affects the user experience. You need to choose the right actuation force based on your application and user needs. Excessive actuation force may cause fatigue, while too little actuation force may easily cause accidental touches.

7. Mounting method and size: Make sure the mounting method (e.g. panel mount, PCB mount) and size of the selected switch match your device or control panel. Consider the size of the mounting hole and the overall depth of the switch.

8. Operating temperature range: Make sure the operating temperature range of the switch meets the requirements of your application environment. The performance of the switch may be affected in extreme temperatures.

9. Certifications and standards: Depending on your application and the regulations in your region, you may need to choose a switch that meets specific certifications and standards, such as UL, CE, etc.

10. Appearance and color: Although functionality is the primary consideration, in some applications, the appearance and color of the switch may also be important, such as to coordinate with the aesthetic design of the device.

By carefully considering these key factors above, you will be able to select the 1NO1NC push switch that best suits your specific application, ensuring system reliability, safety and user experience.

Ready to Simplify Your Control System?

Whether you're upgrading an industrial panel, automating a new device, or simply replacing a worn-out switch, choosing the right 1NO1NC push button can make a significant difference in performance, safety, and reliability.

We offer a wide range of high-quality 1NO1NC button switches — designed for durability, precision, and ease of installation.

Browse our selection now or contact our team for expert advice on the best model for your application.

Your smarter, safer control system starts with the right switch.

HB-TS Series Touch Switch Product Introduction | HBAN Push button

HB-TS Series Touch Switch Product Introduction | HBAN Push button

HBPS series Piezoelectric switch Product Introduction | HBAN Push button

HBPS series Piezoelectric switch Product Introduction | HBAN Push button

HBS1-D series push button switch Product Introduction | HBAN Push button

HBS1-D series push button switch Product Introduction | HBAN Push button

HB-K10 HB-K20 Series Product Introduction | HBAN Push button

HB-K10 HB-K20 Series Product Introduction | HBAN Push button