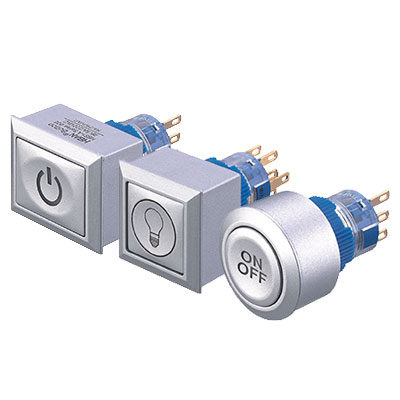

New product 10amp quickly assembled key lock maintain switches industry Emergency stop button

In industrial and mechanical environments, safety is always a top priority.

To ensure the well-being of operators and the protection of equipment, implementing appropriate safety measures is crucial. Among these safety devices, keyed emergency stop buttons stand out as essential components. This article explores the key benefits of keyed emergency stop buttons and their significance in industrial safety.

Keyed emergency stop buttons are not only vital for halting operations in an emergency but also offer flexibility in assembly. You can enhance these buttons by adding a mounting adaptor and a contact block for a complete assembly. This customization ensures that the emergency stop buttons are tailored to fit specific industrial needs, providing both functionality and safety.

1. Enhanced Security:

One of the primary advantages of keyed emergency stop buttons is their ability to enhance equipment security.

Buttons with a mounting hole size of 22mm ensure compatibility with various equipment setups. For those seeking a range of options, E-Stop push buttons are available in both 30mm and 40mm head sizes. This variety allows for flexibility in choosing the right fit for your specific application needs. Whether you require illuminated or non-illuminated versions, these push buttons are designed to enhance operational efficiency and safety across a wide array of industrial environments.

- Mounting Hole Size: 22mm ensures broad compatibility

- E-Stop Options: Available in 30mm and 40mm

- Illumination: Choose between illuminated or non-illuminated variants

This selection empowers you to tailor your control systems with precision, aligning with both existing setups and future upgrades.

By requiring operators to use a designated key for reset, these buttons prevent unauthorized individuals from restarting machinery. This additional layer of security helps reduce the occurrence of accidental activations, safeguarding both operators and equipment from potential harm.

2. Reduced Risk of Accidental Resets:

Keyed emergency stop buttons, rated at 10A/660V, are intricately designed to significantly decrease the likelihood of accidental resets.

Operators must consciously insert the key and turn it to reset the button, minimizing the possibility of unintended activation. To release the E-Stop push button after it has been activated, follow these steps:

- Push the button to trip it: This action ensures the system is safely stopped.

- Release by turning: Simply turn the button to release it from its locked position.

This dual-action mechanism not only provides a safeguard against accidental resets but also ensures that only intentional and deliberate actions will reactivate the system. By requiring both a key turn and a turning release, the design effectively balances safety with functionality.

3. Prevention of Misoperations:

Another advantage of keyed emergency stop buttons is their ability to prevent misoperations. With 1NO1NC contact type and screw terminals, these buttons provide secure connections and versatile integration into control circuitry. The key reset function ensures that only trained and authorized personnel can restart equipment, thus avoiding accidental activations. This feature enhances control and safety during operations, reducing the risk of accidents.

4. Increased Safety Awareness:

The use of keyed emergency stop buttons promotes safety awareness among operators. Operators are aware that the buttons should only be used in emergencies and must follow the correct procedures for operation. With a key reset mushroom head type and plastic shell material, these buttons offer tactile feedback and durability, further reinforcing safety protocols. This fosters a culture of vigilance and responsibility, leading to a safer work environment.

5. Compliance with Regulatory Requirements:

In many industries and environments, compliance with safety regulations is paramount. Keyed emergency stop buttons, with their latching type of operation, meet regulatory standards for safety equipment. Compliance with these regulations not only protects equipment and personnel but also avoids potential fines or legal liabilities. Therefore, incorporating keyed emergency stop buttons is a crucial step for businesses to comply with regulations and ensure workplace safety.

In summary, keyed emergency stop buttons provide critical safety benefits such as enhanced security, reduced risk of accidental resets, prevention of misoperations, increased safety awareness, and compliance with regulatory requirements. When selecting safety equipment, it is essential to consider the advantages of keyed emergency stop buttons and integrate them into safety management plans to ensure workplace safety and reliability.