Comprehensive Guide to Waterproof Push Button Switches

Table of Contents

- What is a Waterproof Pushbutton Switch?

- What are the Standards for Waterproof Button?

- How to Connect the Waterproof Button with LED Product to the Circuit?

- How to Buy Waterproof Push Button Correctly?

- What are the Advantages of Choosing Our Waterproof Push Button Switches?

- How to Maintain and Service Waterproof Pushbutton?

What is a Waterproof Pushbutton Switch?

A waterproof pushbutton switch is a type of switch designed to resist water ingress and moisture, ensuring reliable operation even in wet or humid environments. These switches are commonly used in outdoor applications, industrial settings, marine equipment, and areas where exposure to water or moisture is unavoidable. The waterproofing is typically achieved through the use of rubber seals, gaskets, or specially designed enclosures that prevent water from reaching the electrical components.

Key Features:

- Sealed Housing: Protects internal components from water, dust, and other contaminants.

- Durability: Built to withstand harsh environments, including extreme temperatures and pressure.

- Application Versatility: Used in industries such as marine, automotive, outdoor electronics, and food processing.

What are the Standards for Waterproof Button?

Waterproof pushbutton switches are rated according to international protection standards, commonly referred to as IP (Ingress Protection) ratings. These ratings classify the degree of protection provided by the switch against solids (like dust) and liquids (like water).

Common IP Ratings for Waterproof Switches:

- IP65: Protected against low-pressure water jets from any direction; limited ingress permitted.

- IP67: Protected against immersion in water up to 1 meter for 30 minutes.

- IP68: Protected against continuous immersion in water under conditions specified by the manufacturer (typically deeper than 1 meter).

- IP69K: Designed for high-pressure, high-temperature washdown applications, making them ideal for food processing or industrial cleaning environments.

Why IP Ratings Matter: Understanding IP ratings helps ensure you select the right switch for your application. For example, IP67-rated switches are suitable for outdoor use, while IP69K switches are essential for environments requiring frequent cleaning with high-pressure water.

At our company, we offer a wide range of waterproof pushbutton switches that meet various IP standards. For example, our IP65-rated GQ series vandal-resistant metal buttons are perfect for harsh environments, while our LA38 and XB2 eco-friendly button switches are ideal for applications requiring 10A or 20A current ratings. If you're looking for higher protection, our IP67-rated UL metal AGQ buttons come with multiple mounting hole sizes (16mm, 19mm, 22mm, 25mm, and 30mm) and various illuminated head options. We also offer an innovative IP67 emergency stop button made of durable aluminum alloy with dual-color illumination, providing extra safety in critical environments. For extreme conditions, our IP68-rated piezoelectric switches are available for 16mm, 19mm, and 22mm mounting holes.

How to Connect the Waterproof Button with LED Product to the Circuit?

Connecting a waterproof pushbutton switch to an LED product requires careful attention to the wiring and power requirements of both the switch and the LED.

Step-by-Step Guide:

- Identify the Voltage and Current Requirements: Check the voltage rating of the LED and the switch to ensure they are compatible. Verify the current rating to prevent overloading the circuit.

- Wiring the Switch: Most waterproof pushbuttons are wired in a normally open (NO) configuration, meaning the circuit is completed when the button is pressed.

- Add Resistors if Necessary: If using a basic LED, ensure a resistor is added to limit the current and protect the LED from damage.

- Waterproof Seal: Use waterproof connectors or heat-shrink tubing to seal the connections and prevent water ingress.

Example Circuit:

The picture shows the connection mode of AGQ series waterproof buttons with LED products. The middle three feet are NC normally closed foot, NO normally open foot, and C common foot, and the two terminals next to them are LED lamp feet.

After pressing, the load is powered on to start, and the button light is on.

Understanding N.O. And N.C. In Push Button Switches

When dealing with push button switches, terms like N.O. (Normally Open) and N.C. (Normally Closed) are crucial for understanding their functionality. These terms define the electrical state of the switch when it is not activated:

-

Normally Open (N.O.): The circuit is open, meaning electricity does not flow until the button is pressed. This is ideal for applications where the circuit should only be active when the button is engaged.

-

Normally Closed (N.C.): Converssely, the circuit is closed, allowing electricity to flow until the button is pressed. This setup is used when you need the circuit to be active by default.

These configurations are essential in defining how and when a load is powered. For example, in the AGQ series, the correct connection of NC, NO, and C ensures that loads activate or deactivate as intended, and the LED indicators provide visual confirmation of the switch state.

Understanding these terms and their applications can aid in selecting the right switch for your project, ensuring both functionality and safety. Whether you're working on a hobby project or industrial application, knowing how N.O. And N.C. Work will guide you in wiring the circuits effectively.

How to Buy Waterproof Push Button Correctly?

Choosing the correct waterproof pushbutton switch for your application requires consideration of several factors:

Key Considerations:

- IP Rating: Select the appropriate IP rating based on the level of water and dust exposure the switch will encounter.

- Voltage and Current Ratings: Ensure the switch can handle the operating voltage and current of the circuit.

- Mounting Type: Choose between panel mount, surface mount, or PCB mount options, depending on your installation needs.

- Material: For outdoor or harsh environments, select switches made from stainless steel or high-grade plastic to resist corrosion.

- Size and Aesthetics: Consider the physical size and appearance, especially if the switch is part of a visible control panel.

- Illumination: Decide if you need an illuminated pushbutton, which can be useful for visibility in low-light environments.

With our waterproof pushbutton switches, you get a variety of head types, including ring heads, illuminated power symbols, and even custom designs. Our products are available in multiple LED colors and a wide range of mounting hole sizes. As a trusted supplier with 23 years of experience, we offer competitive pricing, ensuring you receive high-quality products at an excellent value. In addition to pushbutton switches, we also provide emergency stop buttons, touch buttons, piezoelectric buttons, key switches, and various button accessories. Contact us today for a customized solution that fits your needs.

What are the Advantages of Choosing Our Waterproof Push Button Switches?

Our waterproof pushbutton switches are designed with quality and durability in mind, offering several key advantages over other products on the market.

Key Advantages:

- High Durability: Manufactured with high-grade materials that withstand extreme conditions, including saltwater, UV exposure, and temperature fluctuations.

- Enhanced Safety: All switches meet or exceed industry safety standards, ensuring reliable performance in critical applications.

- Customizable Design: We offer a range of customizable options, including different colors, illumination options, and sizes to fit your specific needs.

- Wide Range of Applications: Our switches are suitable for various industries, including automotive, industrial machinery, marine, and consumer electronics.

- Competitive Pricing: Despite superior quality, our pricing remains competitive, providing excellent value for cost-conscious buyers.

As a supplier with the HBAN brand, we have been in the industry for 23 years, offering a wide range of products from waterproof buttons to emergency stop buttons, piezoelectric buttons, and more. Our long-standing expertise and commitment to quality ensure you get the best products for your needs. Reach out to us to learn more about how we can help you with your specific requirements.

How to Maintain and Service Waterproof Pushbutton?

Maintaining a waterproof pushbutton switch is essential for ensuring long-term performance and reliability, especially in harsh or outdoor environments.

Maintenance Tips:

- Inspect Regularly: Check for signs of wear, corrosion, or water ingress.

- Clean the Surface: Use a damp cloth to clean the exterior of the switch. Avoid using harsh chemicals that may degrade the waterproof seals.

- Check Seals and Gaskets: Inspect the rubber seals and gaskets to ensure they are intact and not cracked or worn.

- Test the Switch: Regularly test the switch to ensure proper functionality. If the button feels stiff or unresponsive, consider replacing it.

- Replace Worn Components: If any part of the switch becomes damaged or the waterproof rating is compromised, replace it immediately to avoid failure.

Guide to waterproof push button switches that enhance equipment durability | HBAN Push button

Guide to waterproof push button switches that enhance equipment durability | HBAN Push button

Discover The Surprising Benefits Of Using A Mushroom Push Button | HBAN Push button

Discover The Surprising Benefits Of Using A Mushroom Push Button | HBAN Push button

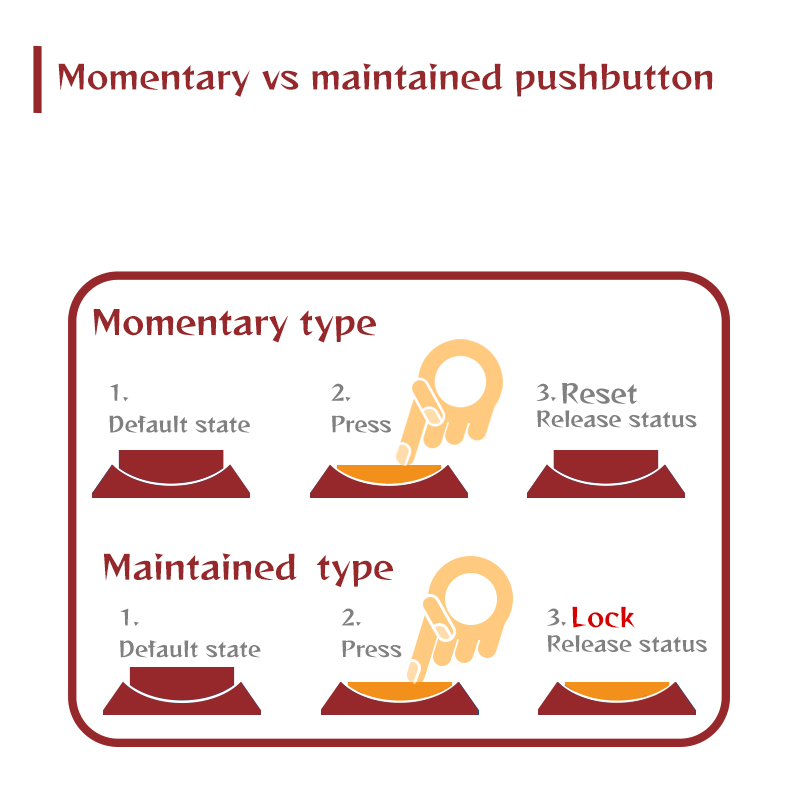

Momentary vs maintained push button | HBAN Push button

Momentary vs maintained push button | HBAN Push button

What is a 12mm push button switch? | HBAN Push button

What is a 12mm push button switch? | HBAN Push button